Table of Contents

What is the difference between holographic grating and ruled grating?

Ruled gratings are the classic type, crafted through a mechanical process. They have grooves that are parallel and uniformly spaced. Imagine drawing lines with a ruler—that’s the basic idea. These gratings can be planar (flat) or concave (curved).

Now, holographic gratings are a bit different. They’re created using a laser interference pattern. This process allows for more flexibility in the groove structure. They can be parallel like ruled gratings, but they can also have unevenly spaced grooves. This allows for optimizing the grating’s performance for specific applications.

Beyond their groove structure, holographic gratings stand out because they can be made on a wider variety of surfaces. While ruled gratings are typically planar or concave, holographic gratings can be found on spherical, toroidal, and other complex shapes. This expands their potential uses in diverse optical systems.

Here’s a deeper dive into the differences between ruled and holographic gratings to help you visualize them better:

Ruled Grating: Imagine a straight ruler that you drag across a surface to draw lines. The lines are equally spaced, reflecting the precision of the ruler. This is the principle behind ruled gratings. They are essentially “ruled” with grooves, creating a precise pattern.

Holographic Grating: Think of two lasers shining onto a surface. The interference pattern formed by their beams creates intricate patterns of light and dark regions. This interference pattern is used to create the grooves on a holographic grating. Unlike the mechanical “ruling” of the ruled grating, this technique allows for more complex groove patterns.

The key takeaway is that holographic gratings offer more flexibility in design and application. Their intricate groove patterns, combined with their ability to be made on diverse surfaces, make them ideal for specific optical tasks.

What is a holographic grating?

Think of it this way: imagine you have two lasers shining at each other. Where the light from these lasers overlaps, they create a pattern of light and dark areas. This pattern is called a standing wave. Now, if you expose a special material to this standing wave, the material will be affected by the light and dark areas. This creates a physical pattern in the material that can diffract light.

This is how a holographic grating is made. It is a powerful tool for controlling light, and it has many applications in areas like spectroscopy, telecommunications, and even optical data storage.

Here’s a little more detail about the process:

Creating the Interference Pattern: The two laser beams used to create the holographic grating must be coherent, meaning their waves are in sync. This ensures the interference pattern is well-defined and stable. The angle between the lasers determines the spacing of the lines in the grating, which in turn affects the way the grating diffracts light.

Exposure to Photosensitive Material: The interference pattern is exposed to a photosensitive material like photoresist or a silver halide emulsion. The areas exposed to the bright parts of the interference pattern are affected differently than those exposed to the dark areas. This creates a physical structure that acts as a diffraction grating.

Developing the Grating: Once exposed, the photosensitive material is developed to create the final holographic grating. This can involve processes like etching, photopolymerization, or chemical development, depending on the material used.

The resulting holographic grating is a remarkable optical element. It’s highly efficient and precise, with features that are much smaller than those created by traditional diffraction gratings. These characteristics make them incredibly useful for a wide range of applications.

What is ruled grating?

The spacing between these grooves (how far apart they are) and the angle they form with the surface (how they are tilted) are critical. These two factors affect how the grating disperses light, which basically means how it separates different colors of light, and also how efficiently the grating works.

Think of it like a comb with teeth. The closer the teeth are together, the finer the comb is. With a ruled grating, closer grooves mean the grating will be able to separate colors of light more precisely.

The angle of the grooves is also important. Imagine tilting the comb. The angle of the teeth would change, and this affects how the comb interacts with your hair. Similarly, the angle of the grooves on a ruled grating influences how the grating interacts with light.

The process of creating ruled gratings is intricate and requires highly skilled technicians and precise equipment. The diamond tool must be extremely sharp and the ruling engine must be able to move with incredible accuracy.

The process begins with a highly polished reflective surface, usually made of metal or glass. The diamond tool is then used to cut grooves into the surface. The tool moves across the surface in a straight line, creating a series of parallel grooves.

The spacing between the grooves is determined by the ruling engine, which is a complex machine that precisely controls the movement of the diamond tool. The angle of the grooves is also controlled by the ruling engine.

The quality of a ruled grating depends on several factors, including the sharpness of the diamond tool, the accuracy of the ruling engine, and the quality of the substrate material. A high-quality ruled grating will have very sharp grooves, uniform spacing, and a smooth surface.

These intricate details are crucial for the grating’s performance and are the reason why ruled gratings are often used in applications where precise light manipulation is essential.

Which type of grating is the best?

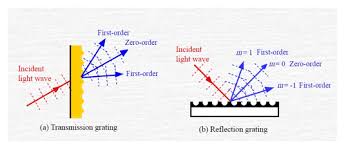

Another popular type is the transmission grating. It’s made by scratching or etching a transparent material with a repeating, parallel pattern. These gratings are commonly used in spectrometers, which are instruments that separate light into its different wavelengths.

Now, when choosing the best grating type, it all comes down to your needs. If stray light control is your top priority, holographic gratings are the way to go. However, if you need maximum efficiency, then ruled gratings might be a better choice.

Here’s a breakdown to help you decide:

Holographic Diffraction Gratings:

Pros:

* Excellent stray light performance

* Often have a smoother surface than ruled gratings, resulting in less scattered light.

* Can be created with more complex patterns, which allows for finer wavelength resolution.

Cons:

* Generally have lower efficiency than ruled gratings.

* Can be more expensive to manufacture.

Ruled Gratings:

Pros:

* Higher efficiency, meaning they can capture more of the light from your sample.

* Less expensive to manufacture.

Cons:

* Can have a rougher surface, leading to more scattered light.

* Not as good at suppressing stray light compared to holographic gratings.

Ultimately, the best grating type depends on your specific application and what you prioritize. If you’re unsure, it’s always a good idea to consult with an expert to help you make the right decision.

Which grating is preferred?

Let’s delve deeper into the reasons why transmission gratings are often chosen. Firstly, transmission gratings are generally more efficient in terms of light throughput. They transmit a greater percentage of the incident light, leading to stronger diffracted beams. This higher efficiency is crucial in applications where maximizing signal strength is paramount, such as spectroscopy.

Secondly, transmission gratings tend to be more robust and less susceptible to damage from environmental factors like dust or scratches. This is particularly important in industrial settings where gratings may be exposed to harsh conditions.

Thirdly, transmission gratings often allow for greater flexibility in terms of design and customization. They can be fabricated with a wider range of groove shapes and densities, enabling precise control over the spectral properties of the diffracted light.

While transmission gratings offer numerous benefits, it’s important to note that reflection gratings have their own advantages. For instance, reflection gratings can handle higher power levels and are often preferred in applications where the incident light is at a high angle. Ultimately, the decision of whether to use a transmission or reflective grating depends on the specific requirements of the application.

What are the two types of diffraction gratings?

A ruled grating is created by a machine called a ruling engine. This machine uses a diamond-tipped tool to cut grooves into a coated surface. This surface is usually glass coated with a thin layer of reflective material. Think of it like a finely detailed record groove, but instead of music, it diffracts light!

Holographic gratings, on the other hand, are created using a holographic process. This process involves interfering two beams of laser light on a photosensitive material. The interference pattern creates a grating with a very precise and consistent spacing of grooves. This leads to highly efficient diffraction and a more uniform spectral response compared to ruled gratings.

So, what are the key differences between these two?

Ruled gratings are typically less expensive to manufacture and can be made with a higher groove density. They are best suited for applications where high resolution is not critical, such as in spectroscopy or in everyday applications like CD players.

Holographic gratings are known for their superior performance and are often used in applications where high resolution is crucial, such as in scientific research, astronomical observations, and laser technology.

Think of it this way: if you need a detailed picture, you’d choose a high-resolution camera. Similarly, if you need a precise and detailed spectrum, you’d use a holographic grating.

The choice between a ruled grating and a holographic grating ultimately depends on the specific application and the required level of performance.

What is the benefit of holographic?

Imagine watching a movie where the characters jump out of the screen and into your living room! That’s the power of holography. It can also be used for research by allowing scientists to study complex objects in three dimensions.

But that’s not all! Holography is also great for security. Think about your driver’s license or passport. It’s hard to fake because of holographic features that are super tough to copy. And because holography can store lots of data, it’s perfect for high-capacity data storage.

Let’s dive a bit deeper into why holography is so cool. Think about those old-fashioned 3D movies you might have seen. You had to wear special glasses to see the depth. Holography is different because it creates a real 3D image that you can see without any glasses! It’s like magic! How does it work? Well, it uses lasers to record and recreate the light waves that bounce off an object. This creates a 3D image that looks incredibly lifelike.

The possibilities with holography are endless! It can be used in museums to create interactive exhibits, in medicine to help surgeons visualize internal organs, and even in art to create truly unique pieces. The future of holography is exciting, and it’s sure to continue to amaze us with its incredible capabilities.

See more here: What Is A Holographic Grating? | Ruled Grating Vs Holographic Grating

What is the difference between ruled and holographic gratings?

Ruled gratings are made by physically cutting grooves into the grating material. This is done using a diamond tool that precisely traces the grooves. The process is similar to engraving.

Holographic gratings, on the other hand, are made using an interference pattern of two laser beams. The interference pattern creates a periodic structure in a photoresist material, which is then transferred to the grating surface.

Let’s dive a little deeper into the differences between these two types:

Ruled Gratings:

Advantages: Ruled gratings are generally less expensive to produce and can be used for a wider range of wavelengths. They also offer better efficiency in the far-infrared region.

Disadvantages: They can have imperfections, known as rulings, which can lead to stray light and reduced resolution. The mechanical cutting process can also limit the groove density and the complexity of the groove profile.

Holographic Gratings:

Advantages: Holographic gratings offer higher groove density, meaning more lines per millimeter. This results in higher resolution and a wider spectral range. The process of creating them also allows for more complex groove profiles, leading to improved efficiency and performance in specific spectral regions.

Disadvantages: They can be more expensive to manufacture. Their efficiency in the far-infrared region is typically lower compared to ruled gratings.

In conclusion, the choice between ruled and holographic gratings depends on the specific application. If high resolution and a wide spectral range are crucial, then holographic gratings are the better choice. However, if cost is a major factor or if a high level of efficiency in the far-infrared region is required, ruled gratings might be more suitable.

How efficient is a holographic grating?

But that’s not all. Special processes can create a holographic grating with a sawtooth profile that’s peaked near 240 nm. This makes it perfect for UV applications where you need high efficiency and low stray light.

Let’s dive a little deeper into why holographic gratings are so efficient. The efficiency of a grating is determined by how well it can diffract light into a specific order. The shape of the grooves on the grating plays a major role in this. A blazed grating has a sawtooth profile, which means the grooves are shaped like tiny triangles. This shape is designed to direct as much light as possible into a single order.

Holographic gratings, on the other hand, are created by interfering two laser beams. This process creates a sinusoidal groove profile, which is more like a wave than a triangle. This might seem like a disadvantage, but it actually gives holographic gratings some advantages.

First, the sinusoidal profile makes it easier to create gratings with very high groove densities. This means you can get a lot more grooves in a small area, which can lead to higher resolution and better performance. Second, the sinusoidal profile helps to reduce the amount of light that’s diffracted into unwanted orders. This is especially important for applications where you need a very pure spectrum, like in spectroscopy.

In conclusion, holographic gratings can be incredibly efficient, especially when you consider their ability to achieve high groove densities and minimize unwanted diffraction. They’re a great choice for applications where you need a high-performance grating, especially in the UV region.

What is a holographic concave grating?

Holographic concave gratings can be made with lower f-numbers than ruled concave gratings. This means that holographic gratings can be designed to focus light more tightly, which is important for many applications. Blazed holographic diffraction gratings typically outperform ruled diffraction gratings in most cases. Why? Because they can be designed to direct more light to a specific order, which makes them more efficient.

Let’s break down why blazed holographic gratings are so awesome. They are created by interfering two beams of laser light on a photosensitive substrate. This process creates a grating pattern that is very precise and uniform. The pattern can be controlled to direct more light to a specific diffraction order.

This blazing process is what makes these gratings so efficient. You see, when light hits a grating, it’s diffracted into multiple orders. In a blazed grating, the grooves are shaped to direct more light to a specific order, making them a great choice for applications where you want to maximize the intensity of a specific wavelength.

Think about it like this. Imagine you have a bunch of mirrors arranged in a specific pattern. This pattern reflects light in different directions, but most of the light gets scattered. Now, imagine that you tilt those mirrors in a way that focuses all the reflected light in one direction. That’s what blazing does for holographic gratings. It makes them more efficient because it focuses more light to a specific order.

This is in contrast to a ruled grating, where the grooves are created by mechanically cutting into a material. These can be less precise, and the resulting grating can be less efficient.

For example, a blazed holographic grating used in a spectrometer can direct more light to the detector for a given wavelength, resulting in a stronger signal. This is important for applications where you need to measure faint signals or analyze samples with low concentrations of the analyte.

So, if you’re looking for a grating that delivers high performance, a blazed holographic grating is likely the way to go!

How do holographic gratings work?

Holographic gratings are made by exposing a light-sensitive material, called photoresist, to an interference pattern created by two beams of light. This exposure changes the properties of the photoresist, creating a pattern of alternating high and low refractive indices. These variations in refractive index act as a diffraction grating, which separates different wavelengths of light.

Here’s a closer look at the process:

1. Photoresist coating: A thin layer of photoresist is applied to a substrate, which is typically a glass or plastic material.

2. Interference pattern exposure: The photoresist is then exposed to an interference pattern created by two coherent beams of light. These beams are carefully aligned so that they intersect at a specific angle, creating a pattern of bright and dark areas.

3. Photoresist development: The exposed photoresist is then developed, removing the areas that were exposed to the brightest parts of the interference pattern. This leaves behind a pattern of ridges and grooves in the photoresist.

4. Grating formation: The resulting pattern acts as a diffraction grating, which diffracts light at specific angles depending on the wavelength of the light and the spacing of the grooves.

The resulting holographic grating can be used to separate light into its constituent wavelengths, much like a prism. Holographic gratings are often used in spectrometers, optical filters, and other optical devices.

The beauty of holographic gratings is their ability to create very precise and fine patterns, which can be difficult to achieve using traditional ruling techniques. This allows for the creation of gratings with high resolving power, meaning that they can separate light into a wider range of wavelengths. Holographic gratings are also more resistant to wear and tear than ruled gratings.

See more new information: musicbykatie.com

Ruled Grating Vs Holographic Grating: Which Is Right For You?

So, you’re looking to split light, huh? You’ve probably heard of ruled and holographicgratings, but you’re not sure which one is best for your needs. Don’t worry, you’re not alone.

It’s a little like choosing between a classic car and a modern electric vehicle – they both get you from point A to point B, but they have different strengths and weaknesses.

Let’s break down the differences between ruled gratings and holographic gratings, so you can make the best choice for your project.

Ruled Gratings

Ruled gratings are like the classic cars of the spectroscopy world. They’ve been around for a long time and they’re reliable workhorses.

How they work:Ruled gratings are made by physically scratching a series of grooves into a reflective surface, like a mirror. The grooves act like tiny prisms, each one deflecting the light at a slightly different angle. Think of it like a staircase – each step is a groove, and the angle of the staircase determines how the light is split.

Pros:

Durable:Ruled gratings can withstand harsh environments and are less prone to damage. They’re like the reliable old truck that just keeps going.

Cost-effective:Ruled gratings are typically cheaper than holographic gratings. Think of them as the budget-friendly option.

High groove density:Ruled gratings can have a very high groove density (the number of grooves per millimeter), which can be important for resolving fine spectral features. It’s like having a high-resolution camera for your light.

Cons:

Limited flexibility: The groove pattern is fixed, so you can’t easily change it to suit different applications. It’s like having a car with a fixed gear ratio, you’re stuck with what you’ve got.

Ghost lines: Ruled gratings can sometimes produce faint “ghost lines” in the spectrum. These lines are caused by imperfections in the ruling process. Think of them as a bit of noise in the system.

Aberrations: Ruled gratings can suffer from aberrations, which can distort the spectral image. It’s like looking through a slightly warped window.

Holographic Gratings

Now, holographic gratings are like the electric cars of the spectroscopy world. They’re more advanced, offer some unique advantages, but also come with a slightly higher price tag.

How they work:Holographic gratings are made by interfering two laser beams on a photosensitive material. This creates a complex, sinusoidal groove pattern. It’s like creating a wave pattern in a pool by interfering two waves.

Pros:

High efficiency:Holographic gratings can be incredibly efficient at dispersing light, making them ideal for applications where light is scarce. Think of them as a powerful solar panel for light.

Low scatter:Holographic gratings produce very little scattered light, resulting in a cleaner spectrum. It’s like having a crystal-clear picture with no static.

Flexible design: The groove pattern of holographic gratings can be customized to suit specific applications. It’s like having a car with a variable gear ratio, you can optimize it for different situations.

Cons:

More expensive:Holographic gratings are generally more expensive than ruled gratings. It’s like buying a luxury car instead of a practical one.

Lower groove density:Holographic gratings typically have a lower groove density than ruled gratings, which can limit their ability to resolve fine spectral features. It’s like having a lower resolution camera for your light.

Sensitive to damage: Holographic gratings can be more sensitive to damage than ruled gratings. It’s like a delicate piece of equipment that needs careful handling.

Choosing the Right Grating

So, how do you decide which type of grating is right for you? Here’s a simple breakdown:

If you need high efficiency and a clean spectrum, a holographic grating is probably the better choice. Think of applications like astronomy, where you need to capture every bit of light.

If you need high groove density, a ruled grating is likely the way to go. Think of applications like Raman spectroscopy, where you need to resolve subtle changes in the spectrum.

If you need a grating that can withstand harsh environments, a ruled grating is more robust. Think of applications like industrial monitoring, where the grating might be exposed to dust, vibrations, or extreme temperatures.

If cost is a major factor, a ruled grating is the more affordable option. Think of applications like student labs or hobbyist projects, where budget constraints are important.

FAQs

Here are some frequently asked questions about ruled gratings and holographic gratings:

Q: Which type of grating is better for astronomy?

A: Holographic gratings are generally preferred for astronomy. Their high efficiency allows them to capture more light from faint celestial objects, and their low scatter results in a cleaner spectrum.

Q: Which type of grating is better for spectroscopy?

A: It depends on the specific application. For high-resolution spectroscopy, ruled gratings are often preferred due to their high groove density. For low-resolution spectroscopy or applications where efficiency is paramount, holographic gratings might be a better choice.

Q: Which type of grating is more durable?

A: Ruled gratings are generally more durable than holographic gratings. They can withstand harsh environments and are less prone to damage.

Q: Which type of grating is more expensive?

A: Holographic gratings are typically more expensive than ruled gratings.

Q: What is the difference between a transmission grating and a reflection grating?

A: A transmission grating transmits light through a series of grooves, while a reflection grating reflects light off of a series of grooves. Both types of gratings can be either ruled or holographic.

Conclusion

Ultimately, the best type of grating for your application will depend on your specific needs. By understanding the advantages and disadvantages of ruled gratings and holographic gratings, you can make an informed decision and choose the grating that will help you achieve your goals.

Let me know if you have any other questions. Happy spectroscoping!

Diffraction Gratings Ruled and Holographic – HORIBA

Classically ruled gratings may be planar or concave and possess grooves, each parallel with the next. Holographic grating grooves may be either parallel or of unequal distribution in order to optimize system performance. Holographic gratings are generated on HORIBA

What is the difference between holographic and ruled diffraction

Ruled gratings have a sawtooth-shaped groove profile tilted at a specific angle (the blaze angle) that is designed to have maximum efficiency at a specific (blaze) wavelength. Edmund Optics

Differences Between Ruled and Holographic Gratings – Newport

While holographic gratings generally exhibit lower scattered light than early ruled gratings, modern control systems and improved master coatings have led to ruled Newport

Ruled Grating vs Holographic Grating – Spectrum Scientific, Inc.

Ruled Grating vs Holographic Grating. Ruled diffraction gratings by the nature of the manufacturing process cannot be produced without defects, which may include periodic Spectrum Scientific, Inc.

Optics Introduction to Diffraction Grating – Thorlabs

ruled grating. Blaze Wavelength: Ruled gratings with a “sawtooth” groove profile have a relatively sharp efficiency peak around their blaze wavelength, while some holographic Thorlabs

Diffraction Gratings: Selection Guidelines | Optics

A holographic grating with 1800 g/mm can have the same efficiency at 500 nm as a blazed, ruled grating. In addition, special processes enable holographic gratings to achieve a sawtooth profile peaked near 240 Photonics.com

Diffraction Gratings Tutorial – Thorlabs

Ruled gratings generally have a higher efficiency than holographic gratings. Holographic grating tend to have a lower efficiency but a broader effective wavelength range. The efficiency of ruled Thorlabs

Understanding and selecting diffraction gratings – Acal BFi

Holographic gratings Initial preparation for holographic grating production is similar to that for ruled gratings, but the coating used for a holographic grating is a photosensitive Acal BFi

Diffraction Gratings – Filtered, Holographic, IR,

Holographic gratings are generally less efficient than ruled gratings because they cannot be “blazed” in the classical sense. Their sinusoidal shape can, in some instances, be altered to approach the efficiency of optometrics.com

Diffraction Gratings 101: Types And Applications

Diffraction Grating

How Does A Grating Work? | Raman For Beginners | Optical Gratings

Diffraction Grating | Light Waves | Physics | Khan Academy

Hyperspectral Microscope: Prism Or Grating?

Using A Cd As Diffraction Grating

Richardson Gratings™ Unboxing

Diffraction Grating | Types Of Grating || Plane Transmitted Grating || Concave Reflective Grating

Link to this article: ruled grating vs holographic grating.

See more articles in the same category here: https://musicbykatie.com/wiki-how/