Table of Contents

What is the Kilbridge and Wester method?

The Kilbridge and Wester method works by assigning tasks to stations in a way that minimizes the idle time of each station. The goal is to ensure that each station has enough work to do without being overloaded. This method is particularly effective when tasks have a fixed processing time. It involves grouping tasks with similar processing times into the same station. By grouping similar tasks together, the Kilbridge and Wester method minimizes the idle time of the assembly line and optimizes efficiency.

The method’s simplicity and efficiency make it a popular choice for line balancing. The Kilbridge and Wester method is often used in industries where production lines are common. It is a valuable tool for manufacturing companies looking to improve their efficiency and reduce costs.

What is the RPW method of line balancing?

Let’s break down each of these metrics to understand their role in the RPW method:

Processing Time: This represents the time it takes to complete a specific task at a workstation. By analyzing the processing time for each task, we can identify potential bottlenecks in the production process.

Balance Delay: This metric quantifies the amount of idle time at each workstation. Ideally, we want to minimize balance delay to ensure that all stations are working efficiently.

Smoothness Index: This measure indicates how evenly the workload is distributed across the workstations. A high smoothness index indicates a well-balanced line with minimal idle time.

Largest Track Efficiency: This metric represents the efficiency of the longest task sequence in the production process. Optimizing the largest track efficiency can significantly improve overall production throughput.

Station Efficiency: This metric measures the efficiency of each individual workstation. It helps us identify stations that may be underutilized or overloaded.

By carefully analyzing these metrics, the RPW method helps us identify areas for improvement and create a more efficient and balanced assembly line. It allows us to streamline operations, reduce waste, and increase productivity. The RPW method is an essential tool for any organization looking to optimize their production process and achieve a more efficient workflow.

What are line balancing methods in garment industry?

Think of it like this: imagine you’re trying to bake a cake with a group of friends. You want to make sure that everyone is working at the same pace so that you can get the cake done quickly and efficiently. You wouldn’t want one person stuck mixing the batter while another person is already frosting the cake. In a garment factory, the same principle applies. You need to ensure that all the workers are doing their part at the same rate so that the garments can be assembled as efficiently as possible.

There are several line balancing methods that garment manufacturers can use, each with its own set of advantages and disadvantages:

1. Workstation Balancing: This method involves assigning tasks to different workstations in a way that ensures each station has a similar amount of work. This is a simple and effective method that can be implemented quickly, but it may not be the most efficient solution in all cases.

2. Precedence Diagram Method: This method starts by creating a diagram that shows the order in which tasks must be performed. Once the diagram is complete, the tasks can be assigned to workstations in a way that minimizes the total time required to complete the process.

3. Line Balancing with Ranked Positional Weights: This method takes into account the importance of different tasks, assigning higher weights to more important tasks. This allows for a more efficient allocation of tasks to workstations, ensuring that the most critical tasks are completed first.

4. Computerized Line Balancing: This method uses software to help manufacturers optimize their line balancing process. It can consider a wider range of factors than manual methods, such as the number of workers, the available equipment, and the time required to complete each task.

It’s important to note that the best line balancing method for a garment manufacturer will vary depending on the specific production process, the available resources, and the desired level of efficiency. By carefully considering these factors, manufacturers can choose the method that will best meet their needs.

What is the largest candidate rule line balancing?

The key idea behind the largest candidate rule is to assign tasks to workstations based on the task time (Te) values. Te represents the time required to complete a task. The rule prioritizes assigning tasks with the longest Te values to the workstations that have the most available time.

Here’s how it works in practice:

1. Identify the task with the largest Te value. This is your “largest candidate.”

2. Assign this task to the workstation with the most available time. This minimizes the idle time of the workstation and ensures that tasks are distributed as efficiently as possible.

3. Repeat steps 1 and 2 for the remaining tasks, always assigning the largest remaining task to the workstation with the most available time.

Example:

Imagine you have four tasks with Te values of 10, 5, 8, and 3 minutes. You also have three workstations. Using the largest candidate rule, you would first assign the task with Te = 10 to the first workstation. Next, you would assign the task with Te = 8 to the second workstation. Then, you would assign the task with Te = 5 to the workstation with the most available time. Finally, you would assign the task with Te = 3 to the remaining workstation.

Benefits of the Largest Candidate Rule

Simplicity: It’s easy to understand and implement.

Quick: It’s a fast method for balancing lines, particularly for smaller problems.

Practical: It often provides a good starting point for balancing lines, even if it may not always lead to the absolute optimal solution.

Limitations of the Largest Candidate Rule

Not always optimal: It may not always find the most efficient line balance, particularly for more complex problems with many tasks and workstations.

Can lead to uneven workloads: If tasks have very different Te values, the largest candidate rule might result in some workstations having significantly more work than others.

While it’s a straightforward method, it’s important to remember that the largest candidate rule is just one approach to line balancing. For more complex scenarios, more sophisticated techniques might be necessary to achieve an optimal balance.

What is the basic concept of line balancing?

Takt time is the rhythm of your production line, representing the rate at which you need to produce parts or products to meet customer orders. Imagine it as the heartbeat of your manufacturing process. You can calculate takt time by dividing the total available work time by the customer demand. For example, if you have eight hours of production time per day and need to produce 100 units, your takt time would be 4.8 minutes (8 hours * 60 minutes / 100 units).

Think of it this way: if your takt time is 5 minutes, you need to produce one unit every 5 minutes to keep up with customer orders. By balancing your production line, you ensure that each workstation completes its tasks within this 5-minute time frame, preventing bottlenecks and delays.

Here’s how line balancing helps achieve this:

Evenly distributing workload: Imagine a production line with five workstations. If one workstation takes 10 minutes to complete its task, while the others take only 2 minutes, you have a bottleneck. Line balancing aims to distribute the workload evenly across all workstations, ideally ensuring that each workstation takes around the same amount of time to complete its assigned tasks.

Optimizing resource allocation: By balancing the line, you can identify areas where you might be over- or underutilizing resources. For example, if a workstation has significantly less work than others, you might need to reallocate some tasks to optimize resource usage.

Reducing cycle time: A well-balanced line minimizes the time it takes to produce a unit, known as the cycle time. This can lead to increased efficiency and productivity, allowing you to produce more units within the same timeframe.

In essence, line balancing is about creating a harmonious production flow, ensuring that each workstation plays its part in the overall rhythm of the line. By doing so, you can achieve a more efficient and responsive production system, ensuring that you consistently meet customer demand.

What are the two types of balancing machines?

Hard-bearing balancing machines use rigid supports to hold the rotor in place. This type of machine is typically used for balancing smaller rotors, such as those found in motors, pumps, and fans. The rigid supports create a more stable environment for the rotor, which results in a more accurate balance.

Soft-bearing balancing machines, on the other hand, use flexible supports. These flexible supports allow the rotor to move slightly during the balancing process. This type of machine is typically used for balancing larger rotors, such as those found in turbines, generators, and compressors. The flexible supports allow the rotor to move freely, which can help to identify and correct imbalances that might not be detected in a hard-bearing machine.

To put it simply, hard-bearing machines are like a rigid platform that holds the rotor steady, while soft-bearing machines are like a springy platform that allows the rotor to move a little. The choice of which type of machine to use depends on the size and type of rotor being balanced.

Think of it like this: imagine trying to balance a spinning top on your finger. If you hold your finger completely still, the top will only spin in one direction. But if you move your finger slightly, the top can spin in many different directions. This is similar to how a soft-bearing balancing machine works. It allows the rotor to move slightly, which helps to identify and correct imbalances.

What is the formula for line balancing?

Let’s break down what these terms mean:

Total task time: This is the sum of the time it takes to complete each individual task in the production process. For example, if you have three tasks that take 10 seconds, 20 seconds, and 30 seconds respectively, the total task time would be 60 seconds.

Number of workstations: This refers to the number of individual work stations along your production line. If you have three separate stations where workers perform different tasks, the number of workstations would be three.

Cycle time: This is the time it takes for a product to move from the beginning of the production line to the end. This time is often determined by the slowest workstation on the line.

By using the LBR formula, you can get a clear picture of how well your production line is balanced. A higher LBR indicates a more balanced line, which means that each workstation is working at a similar pace and there are no bottlenecks.

A balanced production line has several advantages:

Increased productivity: When workstations are balanced, you can expect to produce more goods in a given amount of time.

Reduced waste: A balanced line leads to less downtime and fewer errors, which means less waste of materials and time.

Improved worker satisfaction: When workers are not overworked, they tend to be more satisfied with their jobs.

The LBR is a simple but powerful metric that can help you optimize your production line and improve your overall efficiency. By understanding how to calculate and interpret the LBR, you can identify areas for improvement and make your production process more effective.

See more here: What Are The Different Methods Of Line Balancing? | Kilbridge And Wester Method Of Line Balancing

What is Kilbridge and Wester method?

These heuristics are designed to improve the overall balance and efficiency of the assembly line by considering the relationships between tasks and their precedence constraints. This method offers a more structured approach to line balancing, leading to a more balanced and efficient production process.

Here’s a deeper look at how the Kilbridge and Wester Method addresses the shortcomings of the largest candidate rule:

Addressing the Shortcomings of the Largest Candidate Rule: The largest candidate rule is a simple method for line balancing that focuses on assigning tasks with the longest processing times first. However, it doesn’t always account for precedence constraints, the order in which tasks must be performed. This can result in unbalanced lines where some workstations are overloaded while others are underutilized.

The Kilbridge and Wester Heuristics: The Kilbridge and Wester Method introduces three heuristics to address these shortcomings:

Heuristic 1: Station Assignment Based on Precedence: This heuristic prioritizes assigning tasks that follow directly from tasks already assigned to a station. This ensures that the flow of work is maintained and prevents unnecessary backtracking.

Heuristic 2: Station Assignment Based on Minimal Work: The second heuristic aims to minimize the total work assigned to each station. This helps to balance the workload across the line and prevent any single station from becoming a bottleneck.

Heuristic 3: Station Assignment Based on Task Sequence: This heuristic considers the sequence of tasks and assigns tasks that are performed in close proximity to one another to the same station. This helps to minimize the number of times a product has to be moved between stations and improves the overall flow of the assembly line.

By incorporating these heuristics, the Kilbridge and Wester Method provides a more refined and balanced approach to line balancing, leading to improved efficiency and productivity.

What is Kilbridge and Wester heuristic?

Let’s break down how the Kilbridge and Wester heuristic works:

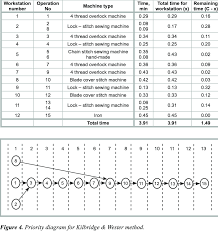

1. The Priority Diagram: Imagine a diagram where you arrange tasks in order of their precedence relationships. This means you list tasks that need to be done before others, so you see the flow of work.

2. Workstations and Tasks: The goal is to create balanced workstations. To do this, you start by assigning tasks to workstations based on their positions in the priority diagram. You try to group tasks that are close together in the diagram, aiming to keep the flow of work smooth.

3. Balancing the Load: This method tries to make sure each workstation has a similar amount of work to do. You might adjust the task assignments slightly to create a more even workload for each station, preventing bottlenecks and delays.

Think of it this way: Imagine building a car. You might have tasks like putting on the tires, installing the engine, and adding the doors. The Kilbridge and Wester heuristic helps you figure out the most efficient way to group these tasks into workstations, so you have a smooth assembly line.

What are the benefits of this method?

Simple and Easy to Understand: The Kilbridge and Wester heuristic is relatively straightforward to grasp and apply, even if you’re new to assembly line balancing.

Reduces Complexity: It helps simplify complex balancing problems by focusing on task relationships and minimizing the number of workstations.

A Good Starting Point: While it’s not always the absolute best solution, it’s a great starting point to get a balanced assembly line, and you can often improve upon it further.

Applicable to Many Industries: This heuristic is a valuable tool for various industries where assembly lines are essential, from manufacturing to services.

The Kilbridge and Wester heuristic provides a helpful framework for balancing assembly lines, making sure work flows smoothly, and ensuring tasks are completed efficiently.

How to solve assembly line balancing problem?

Let’s break down what this means. Imagine you have a production line where workers perform different tasks to assemble a product. The assembly line balancing problem arises when some tasks take longer than others, causing bottlenecks and slowing down the entire process.

The Rank positional weight method and Kilbridge and Wester heuristics are like tools to help you solve this problem.

The Rank positional weight method prioritizes tasks based on their importance and how long they take. This helps you determine the most critical tasks and ensure they are placed strategically on the line.

Kilbridge and Wester heuristics use a more mathematical approach, considering the relationships between tasks and their order to create a balanced workload across workstations.

These methods are like a puzzle, helping you find the best way to distribute tasks to maximize efficiency. By using them, we were able to create a smoother flow of work and ultimately increase production speed.

What is Kilbridge & Wester column (KWC)?

Think of it as a visual way to understand the flow of work. You create a column for each task and then list the tasks in order of their processing time. The column helps you see how long each task takes, and how long it takes to complete the entire process. The KWC allows you to identify potential problems, such as tasks that are taking too long, or tasks that are being done in the wrong order. Then, you can adjust your line to make it more efficient.

Here’s how it works:

1. Identify the tasks: You need to list out all the tasks that are involved in building the air conditioning duct. These could be things like installing the fan, attaching the filter, or connecting the duct to the car’s system.

2. Determine the task times: For each task, figure out how long it takes to complete it. This could be in seconds, minutes, or even hours, depending on the complexity of the task.

3. Create the columns: Draw a column for each task. Label the columns with the task names.

4. Fill in the column: List the tasks in order of their processing time, from the longest task to the shortest task.

You can then use the KWC to analyze the efficiency of your line and identify areas where you can make improvements. You might find that you can:

Reduce the processing time for certain tasks: For example, you might find that a particular task is taking longer than it should, and you can find ways to simplify it or automate it.

Rearrange the order of tasks: Sometimes, you can improve the efficiency of the line by changing the order in which tasks are performed.

Add more workers to certain stations: If one station is being overwhelmed with work, you can add more workers to help out.

The KWC is a simple but powerful tool that can help you improve the efficiency of your assembly line. It can be applied to a wide range of industries, from automotive manufacturing to electronics production.

See more new information: musicbykatie.com

Kilbridge And Wester Method: Optimizing Assembly Line Balancing

Okay, let’s dive into the Kilbridge and Wester method for line balancing. This method is a classic approach used in manufacturing to streamline production lines and maximize efficiency. It’s a powerful tool, but it’s not a magic bullet. To truly get the most out of it, you need a solid understanding of how it works.

Think of it like this: you have a bunch of tasks that need to be done to make a product, right? You want to arrange these tasks in a way that makes the most sense – you want a smooth flow of work, and you want to avoid bottlenecks. That’s where the Kilbridge and Wester method comes in. It helps you organize your tasks in a way that leads to better production efficiency.

Understanding the Basics

At its core, the Kilbridge and Wester method focuses on task precedence – the order in which tasks need to be done. It uses a table format to visualize this order, making it super clear which tasks need to be completed before others.

So, let’s break down how this method works:

1. Identifying Precedence: The first step is to understand the relationship between tasks. What needs to happen before what? This is like a recipe – you can’t start baking until you’ve preheated the oven, and you can’t frost a cake until it’s cooled. Same concept here. We’re looking for those crucial dependencies.

2. Creating a Precedence Table: Once you’ve mapped out your task dependencies, you can create a table. This table is like a roadmap for your production line.

Columns: The columns represent your workstations.

Rows: The rows represent your tasks.

Entries: Inside the table, you’ll put an “X” if a task needs to be completed at that station.

Important Note: The table needs to be arranged in a way that respects task precedence. So, a task can’t be marked as done at a station before it’s been completed at the station where the previous task was done.

3. Analyzing the Table: The real magic happens when you start analyzing the table. You can identify bottlenecks, spot areas where tasks can be grouped together efficiently, and figure out the best flow for your production line.

Applying the Kilbridge and Wester Method

Alright, now let’s get practical. Here’s a real-world example:

Let’s say we’re building bicycles. Our tasks are:

Task 1: Assemble the frame

Task 2: Attach the handlebars

Task 3: Install the wheels

Task 4: Add the seat

Task 5: Install the brakes

Here’s how we can create a precedence table:

| Station | Task 1: Assemble the frame | Task 2: Attach the handlebars | Task 3: Install the wheels | Task 4: Add the seat | Task 5: Install the brakes |

|—|—|—|—|—|—|

| Station 1 | X | | | | |

| Station 2 | | X | | | |

| Station 3 | | | X | | |

| Station 4 | | | | X | |

| Station 5 | | | | | X |

In this case, you can see that each task is assigned to a specific station, and the order of the stations is determined by the task precedence.

Benefits of the Kilbridge and Wester Method

Now, let’s talk about the good stuff – why this method is so useful:

Increased Efficiency: By optimizing the flow of work, you reduce wasted time and effort.

Reduced Bottlenecks: You can spot and address potential bottlenecks, preventing delays in production.

Improved Workload Balance: You can distribute tasks more evenly among workstations, preventing one station from being overloaded while others are idle.

Simplified Production Planning: The method makes it easier to plan and manage production schedules.

Better Utilization of Resources: You can use your equipment and personnel more effectively.

Kilbridge and Wester Method: A Powerful Tool

Remember, this method is just one piece of the puzzle. While it’s a great starting point for line balancing, you might need to combine it with other techniques to get the best results. Think of it as a tool in your toolbox, not a one-size-fits-all solution.

FAQs

1. What are the limitations of the Kilbridge and Wester method?

* Complex Processes: This method can struggle with processes that have a large number of tasks or very complex dependencies.

* Task Duration: It doesn’t factor in the time it takes to complete each task. For a more complete analysis, you’d want to consider the task time.

2. How can I improve the accuracy of the Kilbridge and Wester method?

Iterative Approach: Don’t be afraid to experiment and refine your precedence table. You might need to make adjustments based on real-world observations and feedback.

Consider Cycle Time: Analyze your production process and try to minimize the cycle time (the time it takes to complete one unit of product).

Minimize Work-in-Progress (WIP): Optimize your workflow to keep the amount of work in progress to a minimum.

3. What other line balancing methods are there?

There are a ton of different methods, each with its own strengths and weaknesses:

Ranked Positional Weight Method: This method prioritizes tasks based on their importance.

Longest Operation Time Method: Focuses on assigning tasks with the longest processing times to specific workstations.

Smallest Number of Following Tasks Method: This method minimizes the number of tasks that need to be completed before a particular task can be started.

Line Balancing Using Simulation Software: These tools can help you to model different line configurations and see how they would perform in real-world scenarios.

4. Can I use the Kilbridge and Wester method for service industries?

Absolutely! While it’s often associated with manufacturing, the method can be applied to service industries as well. Think about a call center, a restaurant, or even a healthcare clinic. Any process with a series of steps can be improved using this method.

5. How do I know if the Kilbridge and Wester method is right for my situation?

Analyze Your Processes: Start by carefully mapping out your processes and identifying the tasks involved.

Evaluate Precedence Relationships: Do your tasks have clear dependencies?

Consider Complexity: Is your process fairly simple or very complex?

Experiment: Give the method a try and see how it works for your specific situation.

Remember, line balancing is a crucial element of manufacturing efficiency, and the Kilbridge and Wester method is a powerful tool to help you achieve that goal.

Kilbridge and Wester Method | Manual Assembly Line Balancing …

#Kilbridge_Wester_Method#Line_Balancing#Facility_Planning#manual_Assembly_Line#Industrial_AutomationThis technique has received a good deal of attention in t… YouTube

Solution of the assembly line balancing problem using the rank …

In this study, the assembly line balancing problem has been solved using the Rank positional weight method, which is among the most frequently used heuristics in ScienceDirect

(PDF) A CASE STUDY OF LINE BALANCING USING

The prime objective of line balancing is to distribute tasks evenly over the workstations to minimize the idle time. In this study, ResearchGate

(PDF) Line Balancing Techniques for Productivity

The aim of this article is focusing on increasing the accuracy of standard time by time study and rearranging the work arrangement ResearchGate

(PDF) Application of Line Balancing Heuristics for

For accomplishing the purpose, different line balancing methods named Largest Candidate Rule, Kilbridge & Wester method, and Ranked Positional Weight method carried out for analyzing the line… ResearchGate

A comparative evaluation of assembly line balancing

A comparative evaluation is presented of six popular assembly line balancing heuristics, namely, ranked positional weight, Kilbridge and Wester, Moodie Springer

A Review of Analytical Systems of Line Balancing – JSTOR

* For a more detailed discussion of balance delay and balancing restrictions see M. KILBRIDGE and L. WESTER, “The Balance Delay Problem,” Management Sci. JSTOR

Assembly Line Balancing using Heuristic Approaches in … – CORE

ABSTRACT. Assembly Line Balancing (ALB) plays a vital function especially in the production line. The installation of an assembly line is a long-term decision and requires CORE

A comparative evaluation of assembly line balancing Heuristics

line balancing heuristics, namely, ranked positional weight, Kilbridge and Wester, Moodie and Young, Hoffman precedence matrix, immediate update first fit, and rank and assign Springer

Simulation for Balancing of Assembly Line using Heuristics: A

The assembly line is optimized by using the Kilbridge and Wester Column approach. To test and verify the results, the present and proposed models are simulated using arena IEEE Xplore

Kilbridge Wester Method 2 Line Balacing

Kilbridge And Wester Method | Manual Assembly Line Balancing | Industrial Automation

Kilbridge And Wester Method Part 2

Kilbridge Wester Method 1 Line Balcning

Using Kilbridge And Wester Method For Line Balancing

Kilbridge And Westers Method

Assembly Line Balancing English

Heuristic Methods Like Kilbridge Wester – Process Planning And Line Balancing

Link to this article: kilbridge and wester method of line balancing.

See more articles in the same category here: https://musicbykatie.com/wiki-how/