Table of Contents

What is the reason for bracketing standard failure in HPLC?

Let’s dive deeper into why solvent evaporation can mess up your HPLC results. Imagine your standard solution is like a tiny pool of water with a tiny amount of dissolved solute (your standard). If this pool of water is left exposed to the air, the water molecules will start to evaporate, leaving behind a more concentrated solution. This means you’ll have less of your standard dissolved in the remaining solvent, leading to inaccurate results.

This issue is particularly relevant when using volatile solvents like methanol or acetonitrile. These solvents evaporate quickly, making them more susceptible to this problem. Even a small amount of evaporation can significantly change the concentration of your standard, throwing off your HPLC measurements.

Here’s what you can do to avoid this problem:

Use a sealed container: Store your standard solution in a tightly sealed vial or bottle to prevent evaporation.

Minimize air exposure: Minimize the amount of time your standard solution is exposed to air, especially if using volatile solvents.

Refrigerate your standards: If possible, store your standards in a refrigerator to slow down the evaporation process. This is especially helpful for standards dissolved in volatile solvents.

Prepare fresh standards: For the most accurate results, prepare fresh standards frequently, especially if you’re using volatile solvents.

Use a standard with a longer shelf life: Consider using standards with a longer shelf life, especially if you anticipate using them for extended periods.

Check for signs of evaporation: Before using your standard, carefully inspect the solution for any signs of evaporation, such as a decrease in volume or a change in appearance.

Following these tips will help you maintain the integrity of your HPLC standards, ensuring reliable and accurate results.

What is the bracketing standard in HPLC?

You might be wondering, “What are bracketing standards in HPLC?” They are essentially check standards that help us ensure the accuracy of our results, especially when analyzing a large number of samples.

Think of it like this: Imagine you’re baking a cake, and you want to make sure your oven is at the right temperature. You might use a thermometer to check the temperature at the beginning, middle, and end of the baking process. Bracketing standards in HPLC act like those temperature checks. They’re used to monitor any changes in the instrument’s performance throughout the run.

Why are bracketing standards so important?

The HPLC system can be influenced by factors like temperature fluctuations, changes in mobile phase composition, or even slight variations in the flow rate. These subtle changes might not be noticeable when analyzing a single sample, but over time, they can significantly affect the accuracy of our results. Bracketing standards provide a way to detect and correct these variations.

How does bracketing work?

Calibration Standards: At the beginning of the run, we analyze a set of calibration standards. This helps us establish the baseline for our analysis, similar to setting the zero point on a scale.

Bracketing Standards: Throughout the run, we analyze bracketing standards. These are typically the same standards as our calibration standards, and they’re analyzed at specific intervals. If there are significant differences between the results of the bracketing standards and the initial calibration standards, it indicates a possible shift in the system’s performance.

Corrections: If the bracketing standards show a significant drift, we can adjust our data analysis to account for these changes, ensuring that our results are accurate and reliable.

By incorporating bracketing standards into our HPLC analysis, we can significantly improve the reliability of our results, especially when dealing with large sample sets. This process helps us ensure that our analyses are accurate and consistent, leading to more robust and dependable conclusions.

What causes RSD failure in HPLC?

Priming your HPLC system is super important before running an analysis. It ensures that all the solvent lines are filled with fresh solvent, eliminating any air bubbles. Why are air bubbles a problem? Because they can mess up your results, leading to variations in peak areas and ultimately, RSD failure.

Think of it like this: imagine you’re trying to pour water into a glass, but there’s a big air bubble blocking the way. The water won’t flow smoothly, and you’ll get inconsistent results. The same thing happens in your HPLC system. Air bubbles disrupt the flow of your sample, leading to unpredictable measurements.

Here are a few things to keep in mind when priming your HPLC system to prevent RSD failure:

Use fresh solvent: Make sure you’re using fresh, high-quality solvents to eliminate any potential contaminants.

Purge the lines thoroughly: Spend enough time purging the lines to ensure all air bubbles are removed.

Check for leaks: Inspect the system for any leaks that might introduce air into the system.

Use a degasser: If you’re working with solvents that are prone to forming bubbles, a degasser can help eliminate them.

By following these simple tips, you can ensure that your HPLC system is properly primed and reduce the risk of RSD failure.

What is the standard bracketing method?

Let’s break down why this method is so useful:

Accuracy: By measuring the sample between two standards, you can determine its relative value. If the sample measurement falls closer to the low standard, you know it’s closer in value to the low standard. Conversely, if it’s closer to the high standard, you know it’s closer in value to the high standard.

Consistency: Bracketing helps ensure consistency in your measurements. By measuring the standards repeatedly, you can identify any potential drift or changes in the measuring instrument. This ensures that the sample measurements are accurate and reliable.

Efficiency: Bracketing allows you to measure multiple samples within a single cycle. This saves time and effort compared to measuring each sample individually.

The bracketing method is commonly used in various fields like analytical chemistry, metrology, and quality control. It’s particularly useful when working with samples that have a relatively narrow range of values, making it easier to pinpoint the sample’s position relative to the standards.

What is bracketing calibration?

Let’s break down how bracketing works. Imagine you’re running a series of samples, and you notice that your detector’s signal is slowly decreasing. To correct for this, you’d run a standard at the beginning and end of your sample set. These standards are like reference points, helping you understand how the detector’s response is changing.

By comparing the responses of the standards, you can calculate a correction factor for each sample in between. This factor accounts for the drift in the detector’s response, allowing you to obtain more accurate results.

It’s important to remember that bracketing works best for systematic variations, which are changes that happen gradually and predictably over time. It doesn’t help with random variations, which are unpredictable and difficult to correct for.

Here’s a real-world example to illustrate bracketing calibration:

Imagine you’re analyzing a series of environmental samples for pesticide residues. As you run the samples, you notice that the detector’s response to a specific pesticide is decreasing.

To address this, you decide to use bracketing calibration. You inject a standard solution of the pesticide at the beginning and end of your sample set. By comparing the responses of these standards, you can calculate a correction factor for each sample in between.

This correction factor will account for the gradual decrease in the detector’s response, ensuring that your results for each sample are accurate and reliable.

Think of bracketing calibration like a way to “calibrate” your instrument’s response throughout your analysis. It’s a simple yet effective way to ensure that your results are accurate and reliable, even when the instrument’s response changes over time.

Why add TFA in HPLC?

TFA (trifluoroacetic acid) acts like a magic helper in HPLC, particularly when separating proteins and peptides. It does this by forming ion pairs with the molecules, essentially making them stick together temporarily. This ion pairing makes it easier to separate these molecules because they become more stable and less likely to interact with the column in unwanted ways.

But TFA has another trick up its sleeve: it equilibrates really fast. This means it can quickly adjust to changes in the mobile phase composition, making it perfect for gradient elution. Gradient elution is like a ramp, gradually changing the composition of the mobile phase to separate different molecules. TFA can keep up with this changing environment, ensuring a smooth and reliable separation.

Here’s a more detailed explanation:

Ion-pairing reagents like TFA are essential for HPLC because they help to improve the separation of analytes that are often poorly retained by the stationary phase. TFA creates ionic interactions with the analytes, increasing their hydrophobicity and their ability to bind to the hydrophobic stationary phase. This leads to sharper peaks and improved resolution in the chromatogram.

Equilibration is crucial for gradient elution because it ensures that the mobile phase composition is consistent throughout the separation process. TFA quickly equilibrates, meaning it can rapidly adjust to changes in the mobile phase, such as those introduced by gradient elution. This rapid equilibration helps to maintain a stable separation environment and prevent peak distortions or tailing, which can occur when the mobile phase is not properly equilibrated.

In essence, TFA is a valuable tool in HPLC for separating complex biological molecules like proteins and peptides. Its ability to form ion pairs and equilibrate quickly makes it ideal for gradient elution, which is essential for achieving high resolution and accurate results in these analyses.

What is the principle of bracketing?

Think of it like putting on a pair of special glasses that allow you to see the world with fresh eyes, unfiltered by your usual assumptions and interpretations. By temporarily suspending judgment, you open yourself up to a more complete and nuanced understanding of what’s happening.

Here’s how bracketing works:

1. Identify your preconceptions: Before you can bracket, you need to be aware of your own biases and assumptions about the situation. What do you already “know” about it? What beliefs, values, or experiences might be influencing your perspective?

2. Suspend judgment: Once you’ve identified your preconceptions, the next step is to temporarily set them aside. This doesn’t mean you have to ignore them entirely. It’s more about putting them on hold while you focus on experiencing the situation directly.

3. Focus on the lived experience: With your preconceptions bracketed, you can now fully engage with the experience. Pay attention to your senses, your emotions, and the thoughts that arise without judging them.

4. Describe the experience: After experiencing the situation, try to describe it as accurately as possible. What did you see, hear, smell, taste, and feel? What thoughts and emotions did you have?

Bracketing is a valuable tool for:

Gaining new insights: By suspending your usual way of thinking, you can open yourself up to new perspectives and understandings.

Improving empathy: By bracketing your own preconceptions, you can better understand the experiences of others.

Making more informed decisions: When you’re able to see a situation more clearly, you’re better equipped to make sound decisions.

Bracketing is often used in:

Philosophy: To explore the nature of consciousness and experience.

Psychology: To understand the subjective experiences of individuals.

Art and creative fields: To foster creativity and innovation.

Everyday life: To improve communication, build relationships, and navigate challenging situations.

What is the standard sample bracketing method?

Let’s break down what this means. Think of it like trying to measure the height of a building using a ruler. You need to make sure your ruler is accurate and that you’re using it the same way each time. If your ruler is off, you won’t get an accurate measurement. The same goes for analyzing Si isotopes.

The standard sample bracketing method helps to ensure that the instrument is working correctly and consistently. Here’s how it works:

First, a standard sample with a known isotopic composition is analyzed. This acts as a reference point.

Next, the actual sample is analyzed.

Finally, the standard sample is analyzed again.

By comparing the results of the standard sample analysis before and after the actual sample analysis, any instrumental mass discrimination that occurred during the analysis can be detected and corrected. This ensures that the results for the actual sample are accurate.

Think of it like comparing a known weight to a scale to make sure it’s working correctly. You weigh the known weight, then weigh the object you want to measure, and then weigh the known weight again. If the scale is working correctly, the known weight should read the same each time. This helps to ensure that your object’s weight is accurate.

The SSB method is a powerful tool for determining accurate Si isotopic composition. It ensures that the instrument is working correctly and consistently, which leads to reliable and accurate results. It’s like having a quality control check in place for your measurements.

What is the bracketing technique?

Essentially, you take the same shot multiple times, each at a slightly different exposure. This creates a range of images, from underexposed to overexposed. This way, you’re guaranteed to have at least one shot that’s perfectly exposed, regardless of the lighting conditions.

Think of it as having a safety net for your photos. It’s like having insurance in case you accidentally misjudge the exposure.

Let’s dive a little deeper into how bracketing works:

Exposure Bracketing is the most common type of bracketing. This involves taking multiple photos with different shutter speeds while keeping the aperture and ISO the same. This way, you capture the same scene with different levels of light. For example, you could take a photo at -1 EV, 0 EV, and +1 EV. This means you’re taking three photos: one stop underexposed, one perfectly exposed, and one stop overexposed.

Focus Bracketing involves taking multiple photos with different focus points. This helps you get a sharp image even if you’re not sure exactly where the focus should be.

White Balance Bracketing is ideal for capturing a scene under mixed lighting conditions. This technique involves taking multiple photos with different white balance settings. For example, you could capture the same scene with a warm, neutral, and cool white balance. This way, you have options to choose from when you’re editing your photos.

By using bracketing, you can create a wider range of options for your photos. You can choose the best exposure, focus, or white balance during post-processing. It’s a simple but effective way to ensure that your images are well-exposed and beautifully rendered.

What is RSD failure?

Think about it this way: imagine you’re playing a game and you keep losing. It’s frustrating, right? But for someone with RSD, that frustration can feel magnified. It can feel like the world is ending, like everyone is judging them, and like they’re completely worthless. RSD can make it hard to cope with everyday life, especially in situations where you feel like you’re being criticized or judged.

It’s important to remember that RSD is not your fault. It’s a neurological difference, and with the right tools and support, you can learn to manage it. There are many strategies that can help, including therapy, medication, and lifestyle changes. If you’re struggling with RSD, don’t be afraid to reach out for help. You’re not alone.

What is the RSD limit for HPLC?

You’re right, RSD is a critical aspect of HPLC method validation. It’s essential for ensuring the reliability and consistency of your results.

The USP guideline <621> provides a clear framework for RSD limits in HPLC methods. USP <621> states that the RSD of your reference standard should be 2.0% for 5 injections or more. This means that for 6 injections, your RSD should be 5.0%. An RSD of 10.0% is generally considered the statistical limit of quantitation (LOQ) for the method.

RSD (Relative Standard Deviation) is a measure of the precision of your HPLC method. It tells you how much variation you can expect in your measurements. A low RSD indicates a precise method, meaning that repeated injections of the same sample will produce similar results. A higher RSD indicates a less precise method, which can make it more difficult to reliably quantify your analyte.

Here’s a breakdown of how RSD relates to method validation and why it’s important in HPLC.

Method Validation: RSD plays a crucial role in method validation. It’s one of the key parameters that determines whether your method meets the required standards for accuracy and precision.

Data Reliability: A low RSD gives you confidence in the reliability of your results. You can be sure that your measurements are consistent and accurate.

Analytical Decision-Making: The RSD of your method can influence your analytical decision-making. For example, if you have a high RSD, you may need to make adjustments to your method to improve precision.

Understanding RSD and the USP limits will help you ensure that your HPLC method is robust, reliable, and meets the requirements for regulatory compliance.

See more here: What Is The Bracketing Standard In Hplc? | Bracketing Standard Failure In Hplc

Can %RSD failure cause bracketing failures in HPLC water systems?

Here’s how to think about it:

%RSD (Relative Standard Deviation) tells us how precise our measurements are. A high %RSD means our results are scattered, making it difficult to draw reliable conclusions.

RT (Retention Time) is how long it takes for a compound to travel through the HPLC column and reach the detector. A fluctuating RT indicates inconsistencies in the system, which can lead to poor precision.

Why might bubbles be causing these issues?

Bubbles in the system are the enemy of HPLC. They disrupt the flow of the mobile phase, leading to:

Inconsistent flow rates: This affects how quickly compounds travel through the column, causing RT shifts.

Incomplete mixing of the mobile phase: This can lead to inconsistent elution conditions, making it difficult to obtain reproducible results.

How to troubleshoot and prevent these issues:

1. Degas your mobile phase: Bubbles form due to dissolved gases in the mobile phase. Use a degasser to remove these gases before they reach the system.

2. Check your tubing: Make sure your tubing is properly connected and free of leaks. Air can enter the system through cracks or loose connections.

3. Inspect your pumps: Check the seals and diaphragms in your pumps. Worn or damaged parts can cause air to be drawn into the system.

4. Minimize headspace: Make sure your mobile phase reservoir is full and there’s minimal headspace above the liquid.

5. Use a vacuum degasser: These units are more effective than traditional degassers.

Beyond bubbles, consider these factors:

Temperature fluctuations: Even small changes in temperature can affect the viscosity of the mobile phase, leading to RT shifts.

Column degradation: An aged or damaged column can also contribute to RT changes and %RSD issues.

By addressing these potential causes, you can ensure a stable and reliable HPLC system, leading to more consistent and accurate results.

Is HPLC method development still a problem?

Selectivity is all about how well a column separates different compounds in a mixture. Think of it like sorting laundry: you want to make sure the white socks don’t end up in the dark clothes pile! If a column doesn’t have good selectivity, it won’t separate the compounds properly, and you won’t get accurate results.

Here’s the deal: even with all the advancements, there are still a few things that can affect the reproducibility of selectivity. One is column-to-column variability, meaning that even columns from the same manufacturer can have slight differences in their properties. Another factor is batch-to-batch variation, where even columns from the same batch can have some variability in their performance. This means you could end up with different results depending on which column you use, even if everything else is the same.

Temperature can also affect selectivity. A small change in temperature can make a big difference in how well a column separates different compounds. That’s why it’s important to make sure your HPLC system is kept at a stable temperature.

Mobile phase composition is another factor that can affect selectivity. The mobile phase is the liquid that carries the sample through the column. Even slight changes in the mobile phase composition can change how well the column separates compounds.

Column age can also influence selectivity. Over time, columns can degrade, which can affect their performance. So, it’s important to replace columns regularly to ensure they are working properly.

Cleaning and maintenance play a big role in keeping your HPLC columns performing well. Make sure to clean your columns regularly, and avoid using strong solvents that can damage the stationary phase.

The good news is that there are ways to address these challenges. For example, manufacturers are constantly working to improve the consistency of their columns. There are also methods for evaluating the reproducibility of selectivity, such as column testing and method validation.

So while HPLC method development isn’t always a walk in the park, with a little care and attention, you can overcome the challenges and get reliable results.

What is system suitability in HPLC / GC?

System suitability in HPLC (High-Performance Liquid Chromatography) and GC (Gas Chromatography) is a crucial step in ensuring that your analytical system is performing optimally. It’s a way of verifying that your system is working correctly before you begin your actual analysis. Think of it like a quality control check for your chromatography system.

Bracketing Standards or Check Standards are used to monitor the stability of your system throughout a sequence of samples. The idea is simple: You run a known standard at the beginning and end of a sample set, and compare their results.

This is especially important when dealing with long runs or large sample sets. Over time, slight changes in the chromatography system’s conditions can occur. These changes could include factors like:

Temperature fluctuations in the oven or column

Flow rate variations in the pump

Detector sensitivity drift

Changes in the mobile phase composition

These subtle changes can affect the retention times and peak shapes of your analytes, leading to inaccurate results.

Bracketing Standards help catch these subtle shifts in your system’s performance. If the standard’s results at the beginning and end of your sequence differ significantly, it’s a red flag that something is amiss in your system. This means you need to investigate the cause of the drift and possibly adjust your system to ensure the quality of your data.

To illustrate:

Let’s imagine you’re analyzing a set of 50 samples for a specific compound. You begin by injecting a standard solution of the compound, and record its retention time and peak area. You then proceed to analyze your 50 samples. Finally, you inject the same standard solution again at the end of the sequence.

If the retention time and peak area of the standard are similar in both injections, you can be confident that your system was stable throughout the entire run. However, if the two injections show significant differences, it indicates that your system might have experienced some instability during the analysis. This could mean that your results for the 50 samples might not be accurate or reliable.

In conclusion, using Bracketing Standards is a simple yet effective way to ensure that your HPLC or GC system is performing consistently and producing reliable analytical results.

How to fix HPLC problems?

Let’s face it, HPLC can be a bit of a finicky beast. But don’t worry, troubleshooting HPLC problems doesn’t have to be a headache. The key is to approach it systematically, and a good starting point is to remember the “One Rule”: Change only one thing at a time.

Why is this so important? Because if you make multiple changes simultaneously, you won’t be able to tell which change actually fixed the problem. Imagine changing the mobile phase, the flow rate, and the column temperature all at once – if your results improve, how do you know what single factor was responsible?

Here’s how the One Rule helps you troubleshoot efficiently:

1. Identify the problem: Start by pinpointing exactly what’s wrong with your HPLC system. Is it giving you poor peak shape, inconsistent retention times, or low sensitivity?

2. Formulate a hypothesis: Think about what might be causing the problem. Is it a change in the mobile phase, a clogged column, or an issue with the pump?

3. Change one variable: Based on your hypothesis, change only one variable at a time. For example, if you suspect the mobile phase is the problem, prepare a fresh batch and use that.

4. Observe the results: Did the change you made fix the problem? If so, you’ve successfully isolated the issue. If not, go back to step two, formulate a new hypothesis, and try another change.

By adhering to the One Rule, you’ll quickly identify the root cause of your HPLC issues and get back to collecting reliable data.

Here’s a real-world example to illustrate the One Rule in action:

Let’s say your HPLC system is giving you broad, poorly defined peaks. You decide to troubleshoot the issue.

First, you change the mobile phase. You prepare a fresh batch and inject a standard. But the peak shape remains poor. You change the column, but again, no improvement. Finally, you adjust the flow rate slightly. Suddenly, your peaks become sharp and well-defined!

Because you changed only one thing at a time, you know that the flow rate was the culprit all along. By following the One Rule, you’ve saved yourself a lot of time and frustration, and you’ve effectively isolated and resolved the issue.

See more new information: musicbykatie.com

Bracketing Standard Failure In Hplc: What To Do When It Happens

Hey there, fellow chromatographers! Let’s dive into a common issue we all face: bracketing standard failure in HPLC. This happens when your standards, the crucial reference points for your analysis, don’t behave as expected. It can be frustrating, but don’t worry, we’ll break it down and equip you to handle it like a pro.

Understanding Bracketing Standards

Before we tackle the failures, let’s clarify what bracketing standards are. They’re essentially the “anchors” in your HPLC analysis. You run them before and after your samples to ensure that your method is performing consistently. Think of them as checkpoints, confirming that your system is working correctly and delivering reliable results.

Now, when your bracketing standards show unexpected behavior, it’s a red flag. This failure could manifest in various ways, like:

Drifting Retention Times: Your standard’s peak starts appearing earlier or later than usual.

Area Counts Off: You see significant changes in the peak area compared to previous runs.

Poor Peak Shape: Your peak might become broader, split, or even disappear altogether.

Common Culprits: Identifying the Root Cause

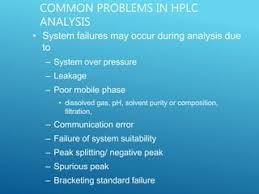

First things first, we need to pinpoint the reason behind this bracketing standard failure. It’s like detective work, but for your HPLC system. Here are some suspects to consider:

1. The Standard Itself:

Degradation: Standards aren’t immortal. They can decompose over time, especially if they’re exposed to light, heat, or moisture. If your standard is old or stored improperly, its chemical composition might be altered, leading to unexpected behavior.

Contamination: A contaminated standard can lead to a whole mess of issues. This could be due to improper handling, contamination from the storage container, or even microbial growth.

Incorrect Concentration: Even a slight error in the concentration of your standard can throw off your entire analysis.

2. Your Injection System:

Injection Volume: If your injection volume is inconsistent, your peak responses will vary, leading to inconsistent areas.

Injection Needle: A clogged or damaged injection needle can mess up your injection process.

Syringe: Similarly, a faulty syringe can cause inconsistencies in the injected volume.

3. Your HPLC System:

Column: A damaged or contaminated column can lead to peak shape changes, shifts in retention time, and unreliable peak areas.

Pump: If your pump isn’t delivering a steady flow rate, your peak responses might suffer.

Detector: A faulty detector can give you erroneous peak areas and potentially distort peak shape.

4. Your Method:

Mobile Phase: A problem with your mobile phase composition, such as degradation or contamination, can affect your analysis.

Flow Rate: Inconsistencies in flow rate can affect your retention times.

Temperature: Temperature fluctuations can affect your retention times and peak shapes.

Troubleshooting Strategies: Finding the Solution

Now that you have a grasp of the potential culprits, it’s time to take action. Here’s a systematic approach:

1. Inspect the Standards:

Check the Storage: Ensure your standards are stored correctly in a cool, dark, and dry place.

Assess Age: If the standard is old, consider replacing it with a fresh batch.

Visual Inspection: Look for any signs of discoloration, precipitation, or contamination.

Concentration Check: Verify the concentration of your standard using a reliable method, like UV spectroscopy.

2. Examine the Injection System:

Clean the Needle: Clean the injection needle thoroughly with a suitable solvent.

Inspect the Syringe: Make sure your syringe is in good condition and working properly.

Verify Injection Volume: Double-check the settings for your injection volume and ensure consistency.

3. Diagnose the HPLC System:

Column Integrity: Evaluate the column’s performance using a suitable test mixture. Consider replacing it if necessary.

Pump Performance: Check the pump’s flow rate and pressure.

Detector Calibration: Calibrate your detector using a known standard.

4. Analyze the Method:

Mobile Phase Freshness: Prepare a fresh batch of mobile phase and check for any signs of degradation.

Flow Rate Consistency: Ensure your flow rate is stable throughout your analysis.

Temperature Control: Double-check your temperature settings and maintain a consistent temperature throughout the run.

Key Takeaways: Prevention is Key

By understanding the common causes of bracketing standard failure, you can proactively minimize the chances of encountering this issue. Here are some tips:

Regular Maintenance: Implement a schedule for regular maintenance of your HPLC system.

Quality Standards: Use high-quality standards from reputable suppliers and store them properly.

Method Validation: Thoroughly validate your HPLC method to ensure its accuracy and precision.

Documentation: Keep a detailed record of your standards, including their expiration dates, storage conditions, and any changes made to your method.

FAQs: Addressing Your Questions

Let’s answer some frequently asked questions:

1. Why do I need bracketing standards in the first place?

Bracketing standards help ensure the reliability and consistency of your HPLC analysis. They act as checkpoints, verifying that your system is performing correctly and delivering accurate results.

2. How often should I run bracketing standards?

It’s best practice to run bracketing standards at the beginning and end of each analytical run. For extended analysis sessions, you might consider running standards at more frequent intervals.

3. What should I do if my bracketing standards fail?

First, identify the source of the problem. Then, take appropriate corrective action, such as replacing the standard, cleaning the system, or adjusting the method.

4. Can I use different bracketing standards for different analytes?

Yes, you can use different standards for different analytes, as long as they are appropriate for the specific analysis.

5. What are some signs that my standards are degrading?

Signs of standard degradation include discoloration, precipitation, a change in odor, or a significant deviation in the expected response.

Remember, troubleshooting bracketing standard failure is all about detective work. With a systematic approach, careful observation, and a little bit of persistence, you can overcome this challenge and ensure the accuracy and reliability of your HPLC results. Good luck, and happy chromatographing!

Bracketing standard failure in long run — Waters Forums

Most likely, the cause is evaporation of your standard’s solvent. Assuming you do not have a chilled sample compartment, nor better cap liners available, the most likely solution is to use each standard vial for consecutive injections only, then not return to that vial once Waters Forum

Bracketing standard concept – Pharmaguideline Forum

The purpose of “Bracketing Standards” or “Check Standards”: Bracketed Calibration. There are times when the HPLC / GC conditions can change during a pharmaguideline.com

%RSD Failing issues — Waters Forums

Dear team, I am facing %RSD failing problems in HPLC waters systems which leads to bracketing failures. Can u guide me what precautions need to take before to start of Waters Forum

Bracketing standard failures — Waters Forums

One of my bracketing standard injections has failed in the middle of the run, but all other brackets after this failure have passed specification. Should I invalidate all samples Waters Forum

Final TIPS and Tricks HPLC Troubleshooting (2) – Agilent

Pressure Issues. Page 6. Determining the Cause and Correcting High Back Pressure. 窶「 Check pressure with/without column – many pressure problems are due to blockages in Agilent

%CV between Bracketing Standards – Chromatography Forum

I am currently having problems with high %CV in bracketing standards on Waters 2495 & 2489. I make up my Standard and carry out two injections from one vial Chromatography Forum

HPLC Troubleshooting Guide

6 www.ace-hplc.com Introduction This troubleshooting guide contains examples of some of the most common problems observed in reversed-phase HPLC (RP-HPLC) HPLC

Bracketing, a simple loading technique that increases

Abstract. A simple loading technique is described for high-performance liquid chromatography that permits almost quantitative sample transfer and recovery, improves ScienceDirect

HPLC Troubleshooting Guide – MilliporeSigma

Correct common HPLC issues to restore column performance, addressing peak problems, retention time, noise, and resolution with chromatograms. MilliporeSigma

How To Deal With Oos Test Results If System Suitability Is Failing

How To Use Bracketing Design For Stability Testing?

System Suitability Parameters Of Hplc | Resolution | Retention Time | Tailing | System Suitability

Lc Troubleshooting | Retention Time Shift | 5 Most Common Causes To Change In Retention Time In Hplc

System Suitablity Parameters For Hplc

What Is Covering Standard In Hplc | Hplc Analysis | Hindi

Akta Xk Column Assembly And Leak Check

Normal Vs Reverse Phase Chromatography Column 101 – Hplc Class 01

Link to this article: bracketing standard failure in hplc.

See more articles in the same category here: https://musicbykatie.com/wiki-how/