Are you looking for an answer to the topic “Does annealed mean heat treated?“? We answer all your questions at the website Musicbykatie.com in category: Digital Marketing Blogs You Need To Bookmark. You will find the answer right below.

Annealing is a heat treatment process that changes the physical and sometimes also the chemical properties of a material to increase ductility and reduce the hardness to make it more workable.The main difference between heat treatment and annealing is that heat treatment is used to obtain different desired properties (ex: increased strength, increased hardness, impact resistance, softening, increased ductility, etc.) whereas annealing is mainly done to soften a metal.Annealing is a heat treatment process which alters the microstructure of a material to change its mechanical or electrical properties. Typically, in steels, annealing is used to reduce hardness, increase ductility and help eliminate internal stresses.

Table of Contents

Is annealing the same as heat treating?

The main difference between heat treatment and annealing is that heat treatment is used to obtain different desired properties (ex: increased strength, increased hardness, impact resistance, softening, increased ductility, etc.) whereas annealing is mainly done to soften a metal.

Is annealed steel heat treated?

Annealing is a heat treatment process which alters the microstructure of a material to change its mechanical or electrical properties. Typically, in steels, annealing is used to reduce hardness, increase ductility and help eliminate internal stresses.

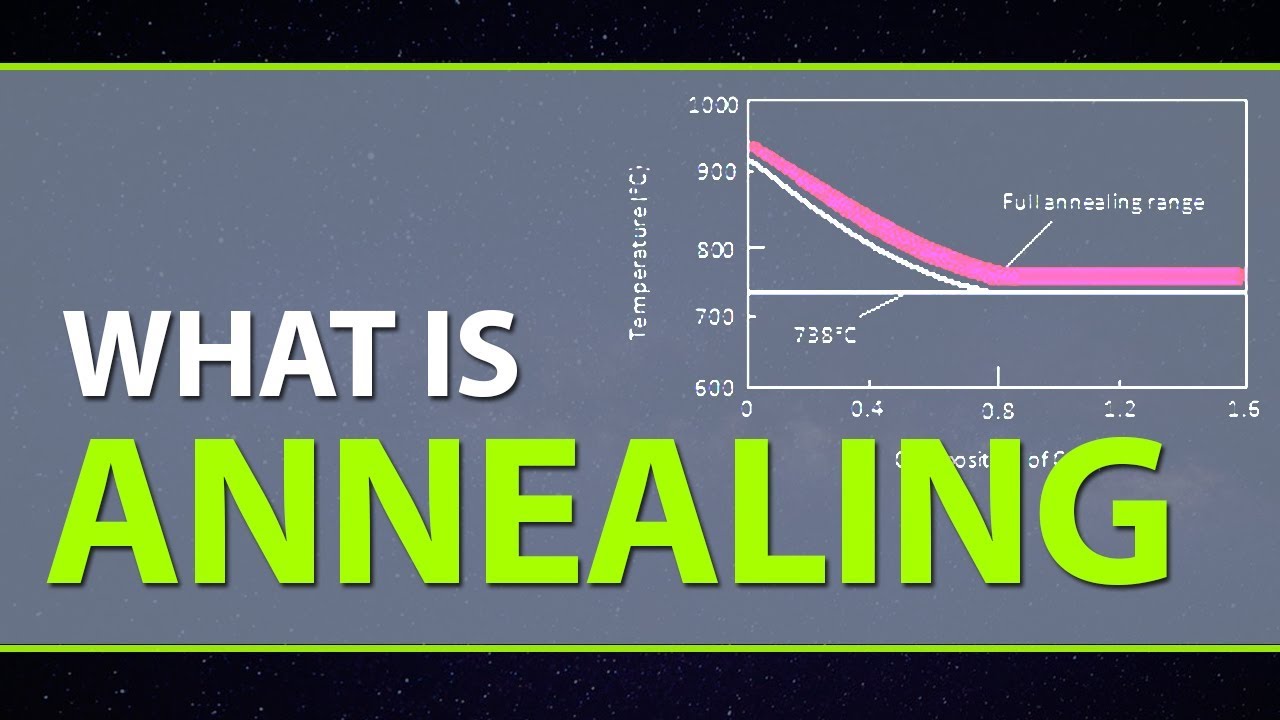

Heat Treatment – Types (Including Annealing), Process and Structures (Principles of Metallurgy)

Images related to the topicHeat Treatment – Types (Including Annealing), Process and Structures (Principles of Metallurgy)

What is annealed heat treatment?

annealing, treatment of a metal or alloy by heating to a predetermined temperature, holding for a certain time, and then cooling to room temperature to improve ductility and reduce brittleness.

What does annealed condition mean?

What is the “Annealed” Condition? Stainless Steel is usually sold in the “annealed” condition. It means that the material is in the “soft” or annealed condition. The 300 series of stainless can not be hardened by heat treatment (like carbon steels) but can be hardened by cold working.

What are the three stages of heat treatment?

- The Heating Stage.

- The Soaking Stage.

- The Cooling Stage.

What is the difference between annealing and tempering process?

Annealing involves heating steel to a specified temperature and then cooling at a very slow and controlled rate, whereas tempering involves heating the metal to a precise temperature below the critical point, and is often done in air, vacuum or inert atmospheres.

What happens when metal is annealed?

Annealing steel or any other metal involves heating it to a specific temperature and allowing it to cool at a specified rate. Doing so removes impurities in the grain, increasing the metal’s ductility and reducing its hardness.

See some more details on the topic Does annealed mean heat treated? here:

What is the Difference: Tempering vs. Annealing? – Mead Metals

Tempering and annealing are both methods of heat treating metal. The purpose of heat treating is to intentionally alter the physical (and …

Difference Between Annealing and Tempering – Metal …

Annealing involves heating steel to a specified temperature and then cooling at a very slow and controlled rate. Annealing is commonly used to:.

Difference Between Heat Treatment and Annealing – Pediaa …

Annealing is a heat treatment process used to soften materials or to obtain other desired properties such as machinability, electrical …

Annealing / Normalising – Heat Treatment – Bodycote plc

Annealing is a heat treatment process which alters the microstructure of a material to change its mechanical or electrical properties.

How long does annealing last?

The ideal cooldown rate for annealing steel is about 70 F per hour, down to about 500 F. In other words, a piece of steel that’s cooling from 1500 F to 500 F should ideally take about 14 hours. Actual ideal times will vary by grade of steel, but that’s a decent rule of thumb.

What are annealed metals used for?

Annealing is a heat treatment process which alters the microstructure of a material to change its mechanical or electrical properties. Typically, in steels, annealing is used to reduce hardness, increase ductility and help eliminate internal stresses.

What is the purpose of annealing process?

The main purpose of Annealing is to reduce the hardness of a material.

What is the difference between annealing hardening and tempering?

The main difference between annealing hardening and tempering is that annealing is done to soften a metal or an alloy and hardening is done to increase the hardness of a metal or alloy whereas tempering is done to reduce the brittleness of quenched metal or alloy.

Why do we anneal steel?

Annealing makes metals more formable. When metal is stronger and more ductile, it gives manufacturers more leeway in the fabrication process. There is less risk of material fracturing from bending or pressing. Annealing can also improve a metal’s ability to be machined and improve the lifespans of tools.

What is Annealing | Types of Annealing Process | Purpose Advantages of Annealing

Images related to the topicWhat is Annealing | Types of Annealing Process | Purpose Advantages of Annealing

Is solution treated and annealed the same thing?

Solution annealing (also referred to as solution treating) is a common heat-treatment process for many different families of metals. Stainless steels, aluminum alloys, nickel-based superalloys, titanium alloys, and some copper-based alloys all may require solution annealing.

What is the effect of annealing?

The annealing treatment increases the system’s strength by reducing dislocation emission sources and improves material ductility through strengthening grain boundaries’ resistance to intergranular cracks.

What is the difference between solution heat treatment and precipitation heat treatment?

Solid solution strengthening involves formation of a single-phase solid solution via quenching. Precipitation heat treating involves the addition of impurity particles to increase a material’s strength.

What are the types of annealing?

- Complete annealing.

- Isothermal annealing.

- Incomplete annealing.

- Spherification annealing.

- Diffusion annealing (uniform annealing)

- Stress Relief annealing.

- Recrystallization annealing.

What is the difference between annealing and normalizing?

The main difference between annealing and normalizing is that annealing allows the material to cool at a controlled rate in a furnace. Normalizing allows the material to cool by placing it in a room temperature environment and exposing it to the air in that environment.

What are the five basic heat treatment process?

Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching.

What is the difference between annealing heat treatment and tempering heat treatment in glass forming?

Tempering and annealing are both heat treatment processes that alter the physical and chemical properties of metals to prepare them for manufacturing. The difference between the two processes relate to the temperatures and cooling rates, with tempering happening at lower temperatures but with faster cooling times.

Is cold rolled steel annealed?

During cold rolling, the steel is annealed, or exposed to heat and allowed to cool, which improves ductility. The steel is then shaped at room temperature, greatly increasing the hardness of the finished product.

Does annealing make metal stronger?

Hot working or cold working after the annealing process alters the metal structure, so further heat treatments may be used to achieve the properties required. With knowledge of the composition and phase diagram, heat treatment can be used to adjust from harder and more brittle to softer and more ductile.

What is heat treating metal?

Practically nothing can be manufactured without heat treating, a process in which metal is heated and cooled under tight controls to improve its properties, performance and durability. Heat treating can soften metal, to improve formability. It can make parts harder, to improve strength.

annealing process | Types of Annealing Process | annealing heat treatment process#heattreatment

Images related to the topicannealing process | Types of Annealing Process | annealing heat treatment process#heattreatment

How does annealing affect steel?

Annealing alters the physical and chemical properties of the metal to increase ductility and reduce hardness. This facilitates shaping, stamping or forming processes, and allows the metal to be cut more easily. Annealing also enhances electrical conductivity.

Do you quench after annealing?

To anneal a metal you must bring it up to a critical temperature with a torch and then quench the hot metal in water. Be careful not to heat metals beyond the annealing temperature or they will melt.

Related searches to Does annealed mean heat treated?

- does annealed mean heat treated flour

- annealing heat treatment

- does annealed mean heat treated pallets

- difference between annealing and normalizing

- annealing process

- does annealed mean heat treated wood

- does annealed mean heat treated steel

- does annealed mean heat treated aluminum

- annealing vs tempering

- what is tempering in heat treatment

- normalizing heat treatment

- does annealed mean heat treated or not

- annealed vs heat treated

- annealing meaning

- does annealed mean heat treated stainless steel

Information related to the topic Does annealed mean heat treated?

Here are the search results of the thread Does annealed mean heat treated? from Bing. You can read more if you want.

You have just come across an article on the topic Does annealed mean heat treated?. If you found this article useful, please share it. Thank you very much.